The Continental C90 parts manual is an essential resource for aircraft owners and mechanics‚ providing detailed specifications‚ repair procedures‚ and maintenance guidelines for optimal engine performance and longevity. It covers everything from routine inspections to complex overhauls‚ ensuring safe and efficient operation of the Continental C90 engine. Designed for experimental and small aircraft‚ this manual is a cornerstone for maintaining airworthiness and addressing common issues effectively. Regular updates and clear diagrams make it indispensable for professionals and enthusiasts alike‚ ensuring compliance with aviation standards.

1.1 Overview of the Continental C90 Engine

The Continental C90 engine is a reliable‚ air-cooled‚ four-cylinder powerplant designed for small aircraft. Producing between 90 and 95 horsepower‚ it is widely used in experimental and light aircraft due to its simplicity and fuel efficiency. Known for its durability and ease of maintenance‚ the engine features a robust design with a displacement of 201 cubic inches. Fuel efficiency is a key advantage‚ making it a popular choice for pilots seeking cost-effective performance. Regular maintenance‚ as outlined in the parts manual‚ ensures optimal reliability and longevity.

1.2 Importance of the Parts Manual for Maintenance and Repair

The Continental C90 parts manual is crucial for maintaining and repairing the engine effectively. It provides detailed diagrams‚ part numbers‚ and repair procedures‚ ensuring mechanics can accurately identify and replace components. Regular inspections and timely replacements prevent costly damage and enhance safety. Without the manual‚ diagnosing issues and sourcing correct parts becomes challenging. It serves as a comprehensive guide‚ helping owners and technicians maintain the engine’s performance‚ efficiency‚ and longevity‚ adhering to aviation standards and ensuring airworthiness. Proper use of the manual is essential for safe and reliable operation.

Historical Background of the Continental C90

The Continental C90 engine has a rich history‚ introduced in the mid-20th century as a reliable powerplant for small aircraft‚ becoming a trusted choice in aviation.

2.1 Development and Evolution of the Continental C90 Engine

The Continental C90 engine was introduced in the mid-20th century‚ designed for small aircraft‚ offering reliability and efficiency. Initially rated at 90 horsepower‚ it became popular for training and light aircraft. Over time‚ the engine underwent improvements‚ including enhanced materials and technologies‚ to boost performance and durability. Its compact‚ air-cooled design made it ideal for various aviation applications. The C90’s evolution reflects advancements in aviation engineering‚ ensuring it remains a trusted powerplant for pilots and aircraft owners worldwide.

2.2 Key Applications of the Continental C90 in Aviation

The Continental C90 engine is widely used in small‚ single-engine aircraft‚ including training planes‚ agricultural aircraft‚ and experimental designs. Its reliability and fuel efficiency make it ideal for flight schools and private pilots. Additionally‚ the C90 powers crop dusters and utility aircraft‚ where durability and consistent performance are crucial. Its compact design and versatility also suit experimental aircraft projects‚ making it a popular choice for enthusiasts and aviation professionals seeking a dependable powerplant for various flying needs.

Engine Specifications and Technical Features

The Continental C90 engine delivers 95 horsepower at 2‚700 RPM‚ featuring a compact design and efficient fuel consumption. Its robust construction ensures durability‚ while the air-cooled system enhances reliability. Fuel efficiency and consistent performance make it a reliable choice for small aircraft‚ supported by detailed specifications in the parts manual for optimal maintenance and upgrades.

3.1 Horsepower and Performance Capabilities

The Continental C90 engine produces 95 horsepower at 2‚700 RPM‚ offering a reliable power output for small aircraft. Its performance capabilities are optimized for lightweight and experimental planes‚ ensuring smooth operation across various conditions. Fuel efficiency and consistent RPM delivery make it a preferred choice for pilots seeking durability and responsiveness. The engine’s design balances power and fuel consumption‚ making it suitable for both training and recreational flying‚ as detailed in the parts manual for maintenance and upgrades.

3.2 Fuel System and Efficiency

The Continental C90 engine features a carbureted fuel system designed for simplicity and reliability. It operates efficiently with avgas‚ providing consistent performance across various altitudes. However‚ owners must be cautious with E10 fuel‚ as it can cause corrosion and damage over time. Regular inspection of fuel lines and carburetors is essential to maintain efficiency. The manual recommends using high-quality fuel filters and adhering to strict maintenance schedules to prevent fuel-related issues and ensure optimal engine operation. Proper fuel management enhances both performance and longevity.

3;3 Cooling and Lubrication Systems

The Continental C90 engine employs an air-cooled system for efficient heat management‚ reducing reliance on complex cooling fluids. The pressure-fed lubrication system ensures consistent oil distribution‚ safeguarding moving parts from wear. Regular inspection of oil hoses and filters is critical to maintain optimal performance. The manual recommends using high-quality aviation oils‚ such as SAE 40 or 50‚ to prevent overheating and corrosion. Proper maintenance of these systems is vital for extending engine lifespan and ensuring reliable operation under various flight conditions.

Understanding the Continental C90 Parts Manual

The Continental C90 parts manual is a comprehensive guide designed to help users identify‚ locate‚ and replace engine components efficiently. Organized clearly‚ it features detailed diagrams‚ part numbers‚ and repair procedures‚ making it an indispensable tool for maintenance professionals and aircraft owners.

4.1 Structure and Organization of the Manual

The Continental C90 parts manual is meticulously organized into clear sections‚ ensuring easy navigation. Each chapter focuses on specific components‚ such as engine assembly‚ fuel systems‚ and overhaul procedures. Detailed diagrams and part numbers are included for quick identification. Bullet points and sub-sections break down complex information‚ making it accessible for users. The manual also includes step-by-step repair guides and maintenance schedules‚ ensuring that even novice mechanics can follow along. This structured approach makes the manual a vital resource for anyone working with the Continental C90 engine.

4.2 How to Identify and Locate Parts

Identifying and locating parts in the Continental C90 manual is streamlined through clear part numbers and detailed diagrams. Each component is indexed for quick reference‚ with cross-referenced tables to ensure compatibility. Diagrams highlight part locations within engine assemblies‚ simplifying identification. Users can also search by function or assembly group. Digital versions often include hyperlinks for faster navigation. This system ensures that mechanics and owners can efficiently locate and order the correct parts‚ minimizing downtime and ensuring accurate repairs. Regular updates keep the information current and reliable.

Key Sections of the Parts Manual

The manual features sections on engine assembly‚ overhaul procedures‚ and required tools‚ ensuring comprehensive coverage for maintenance and repairs. Clear organization aids quick access to critical information.

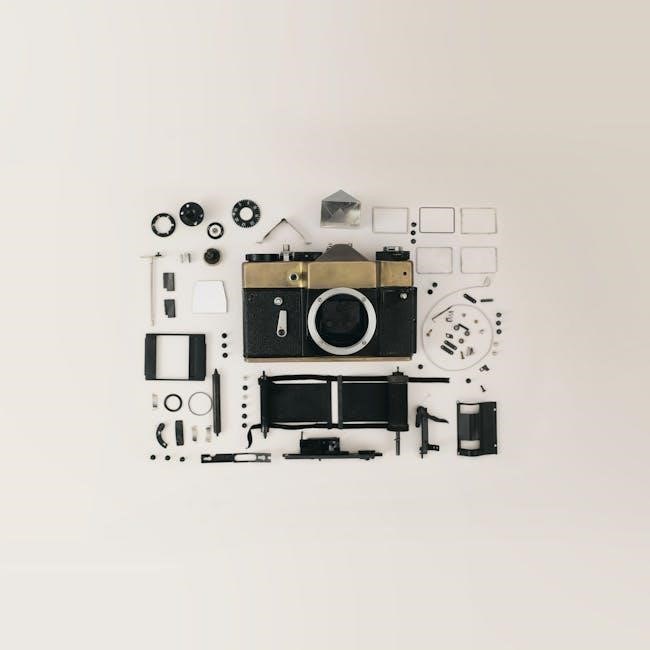

5.1 Engine Assembly and Components

The Continental C90 parts manual provides detailed insights into the engine assembly‚ highlighting key components such as cylinders‚ pistons‚ crankshafts‚ and valves. Each part’s role in ensuring smooth operation is explained‚ along with specifications for proper installation and alignment. Detailed diagrams and exploded views help visualize complex assemblies‚ making it easier to identify and replace components. This section is crucial for understanding how the engine functions as a cohesive unit‚ ensuring optimal performance and longevity through accurate assembly and maintenance practices.

5.2 Overhaul and Repair Procedures

The Continental C90 parts manual outlines comprehensive overhaul and repair procedures‚ ensuring engine longevity and reliability. Step-by-step guidelines cover disassembly‚ inspection‚ and reassembly of critical components. Key steps include piston replacement‚ cylinder refurbishment‚ and crankshaft inspection. Diagrams and torque specifications are provided for precise repairs. This section emphasizes proper techniques to restore engine performance and prevent future issues‚ making it indispensable for mechanics and aircraft owners performing maintenance or major overhauls. Adherence to these procedures ensures safety and efficiency in returning the engine to optimal condition.

5.3 Tools and Equipment Required

The Continental C90 parts manual specifies essential tools and equipment for engine maintenance. Standard tools include wrenches‚ pliers‚ and screwdrivers‚ while specialized tools like piston ring compressors and bearing pullers are necessary for complex tasks. Workstands and lifting equipment are recommended for safe engine handling. Diagnostic tools‚ such as compression testers‚ help identify issues. Safety gear‚ including gloves and goggles‚ is crucial for protecting mechanics. Proper equipment ensures accurate repairs and compliance with aviation standards‚ minimizing risks and downtime during maintenance or overhaul procedures. Some tools may require ordering from authorized suppliers.

Performance Upgrades and Modifications

The Continental C90 engine can be enhanced through specific upgrades‚ such as aftermarket components or performance kits‚ to increase horsepower and efficiency. Experimental aircraft owners often explore these modifications to optimize their engine’s output‚ ensuring improved flight capabilities while maintaining safety and reliability. Upgrades must comply with aviation standards and regulations to preserve airworthiness certification. Always consult the parts manual for compatibility and installation guidelines to avoid compromising engine integrity or performance. Regular inspections are crucial after modifications to ensure optimal functioning and longevity of the engine.

6.1 Increasing Horsepower and Efficiency

Enhancing the Continental C90 engine’s performance involves targeted modifications to boost horsepower and fuel efficiency; Upgrading to high-performance components‚ such as lightweight pistons or improved cylinder heads‚ can significantly increase power output. Optimizing the fuel system with high-flow fuel injectors or advanced carburetors can improve combustion efficiency‚ leading to better mileage and reduced emissions. Tuning the engine for peak performance at specific altitudes or operating conditions can also yield impressive results. Always consult the parts manual for compatibility and safety guidelines to ensure modifications align with aviation standards and maintain airworthiness certification.

6.2 Popular Aftermarket Parts and Accessories

The Continental C90 engine supports various aftermarket upgrades to enhance performance. Lightweight pistons and high-performance cylinder heads are popular for increasing horsepower. High-flow fuel injectors and aftermarket carburetors improve fuel efficiency and combustion. Stainless steel exhaust systems reduce weight and increase longevity. Performance air filters enhance airflow for better engine breathing. These modifications‚ when installed correctly‚ can significantly improve the engine’s overall performance and reliability. Always consult the parts manual for compatibility and installation guidelines to ensure safe and effective upgrades.

Maintenance Tips for the Continental C90

Regular inspections and adherence to service intervals are crucial for maintaining the Continental C90 engine. Addressing wear early prevents costly overhauls. E10 fuel compatibility issues require careful planning. Always use genuine or compatible parts to ensure reliability. Consult the parts manual for specific guidelines to maintain optimal performance and longevity.

7.1 Regular Inspection and Service Intervals

Regular inspections are vital for ensuring the Continental C90 engine operates safely and efficiently. Follow the parts manual’s recommended service intervals to identify wear and tear early. Inspect fuel lines‚ spark plugs‚ and cylinder heads for signs of deterioration. Addressing issues promptly prevents major overhauls. Pay attention to E10 fuel compatibility to avoid corrosion. Use genuine or approved parts for replacements to maintain performance and reliability. Keep detailed maintenance records for tracking and future reference.

7.2 Tips for Extending Engine Longevity

To extend the life of your Continental C90 engine‚ adhere to the parts manual’s maintenance schedule and use genuine or approved parts. Monitor engine temperatures and oil levels to prevent overheating and lubrication issues. Avoid aggressive flying maneuvers that stress the engine. Store the aircraft properly during extended downtime to protect against corrosion. Regularly clean and inspect air filters for optimal performance. Log all maintenance activities to track wear and ensure timely repairs‚ maximizing the engine’s lifespan and reliability.

Troubleshooting Common Issues

Common issues with the Continental C90 include rough engine performance‚ low oil pressure‚ and fuel system leaks. Consult the parts manual for diagnostic steps and solutions. Addressing problems early prevents costly overhauls and ensures safe operation. Always follow recommended repair procedures to maintain engine integrity and performance.

8.1 Identifying and Diagnosing Engine Problems

Identifying issues with the Continental C90 engine often starts with observing unusual performance‚ such as rough running or low oil pressure. Refer to the parts manual for diagnostic guidelines. Listen for abnormal sounds and monitor instrument readings. Conduct routine inspections to spot wear or leaks early. Use the manual’s troubleshooting charts to pinpoint causes of common faults. Early detection prevents minor issues from becoming major overhauls‚ ensuring reliable engine operation and safety.

8.2 Common Faults and Their Solutions

Common faults in the Continental C90 include oil leaks‚ worn piston rings‚ and faulty spark plugs. Oil leaks often stem from gasket wear‚ requiring replacement. Worn piston rings may cause low compression‚ needing cylinder overhaul. Fouled spark plugs should be cleaned or replaced to restore ignition. Consult the parts manual for specific repair procedures. Addressing issues promptly prevents further damage‚ ensuring reliable performance and extending engine lifespan. Regular maintenance can help mitigate these common problems effectively.

Safety Precautions and Best Practices

Always wear protective gear‚ including gloves and safety glasses‚ when handling fuel or hazardous materials. Ensure proper ventilation to prevent fume inhalation. Follow all guidelines in the parts manual to avoid accidents during maintenance or repair.

9.1 Handling Fuel and Hazardous Materials

When handling fuel and hazardous materials for the Continental C90‚ always wear protective gloves and eyewear. Ensure proper ventilation to avoid inhaling harmful fumes. Use approved containers for storing and disposing of hazardous substances. Refer to the parts manual for specific guidelines on fuel handling to prevent accidents. Be aware of fuel compatibility and avoid using E10 fuel‚ as it may cause corrosion or damage to engine components. Follow all safety protocols to minimize risks during maintenance or repair procedures.

9.2 Safety Guidelines for Engine Maintenance

Always disconnect the battery before starting maintenance to prevent accidental engine start. Use jack stands for aircraft support and ensure the area is clear of flammable materials. Wear protective gear‚ including safety glasses and gloves‚ when handling tools or chemicals. Follow torque specifications to avoid damaging components. Keep the work area clean to prevent contamination of parts. Refer to the parts manual for specific safety precautions and ensure all procedures are conducted in a well-ventilated space.

Resources and Support for Continental C90 Owners

Owners of the Continental C90 can access extensive support through online forums‚ specialized aviation communities‚ and authorized service centers. These resources provide troubleshooting tips‚ repair guidance‚ and advice on aftermarket parts. Communities like AOPA and EAA offer valuable insights and shared experiences‚ while authorized centers ensure genuine parts and compliance with aviation standards. Regular updates and technical assistance are also available to help owners maintain their engines efficiently and safely.

10.1 Online Communities and Forums

Online communities and forums dedicated to the Continental C90 engine serve as invaluable resources for owners and mechanics. Platforms like AOPA and EAA provide forums where users can share experiences‚ ask questions‚ and access troubleshooting tips. Specialized aviation forums often feature discussions on maintenance‚ repair‚ and upgrades‚ offering insights from experienced pilots and technicians. These communities also host threads on aftermarket parts‚ performance enhancements‚ and common issues‚ making them a vital support network for C90 owners seeking guidance and solutions. Real-time engagement fosters collaboration and problem-solving‚ ensuring owners can address challenges effectively.

10.2 Authorized Service Centers and Repair Shops

Authorized service centers and repair shops are crucial for maintaining the Continental C90 engine. Factory-trained technicians ensure compliance with manufacturer standards‚ guaranteeing safety and performance. These centers provide access to genuine parts‚ specialized tools‚ and updated technical bulletins. Regular maintenance by authorized personnel helps prevent issues and extends engine life. Owners can locate these centers through Continental Motors’ official website or local aviation directories. Trustworthy service ensures reliability for both recreational and professional aviation needs‚ upholding the engine’s reputation for durability and efficiency.

Future Trends in Aviation Engines

The aviation industry is moving toward electric propulsion and hybrid systems‚ reducing emissions and noise. Advancements in fuel efficiency and alternative fuels are expected to dominate future engine designs‚ ensuring sustainability and performance for engines like the Continental C90.

11.1 Advances in Engine Technology

The aviation industry is rapidly advancing‚ with a strong emphasis on electric and hybrid propulsion systems. These innovations aim to enhance fuel efficiency and reduce emissions‚ aligning with global sustainability goals. Additionally‚ advancements in engine materials‚ such as lightweight alloys‚ are improving durability and performance. Enhanced cooling and lubrication systems are also being developed to optimize engine longevity and operational efficiency. These technological strides ensure that engines like the Continental C90 remain viable and efficient in the evolving aviation landscape.

11.2 Impact of Fuel Efficiency Requirements

Stricter fuel efficiency requirements are reshaping engine design and maintenance practices. Modern engines must now meet higher standards to reduce emissions and operating costs. For the Continental C90‚ this means optimizing combustion systems and exploring lightweight materials to enhance performance. Fuel-efficient technologies are becoming essential‚ even for legacy engines. Additionally‚ the shift toward alternative fuels‚ such as E10‚ requires careful consideration of compatibility and potential upgrades. These changes underscore the importance of adapting to evolving regulatory and environmental demands in aviation. Owners and mechanics must stay informed to ensure compliance and maintain engine reliability.

The Continental C90 parts manual is a comprehensive guide empowering owners and mechanics to maintain‚ repair‚ and optimize the engine for safe and efficient operation. By adhering to its instructions‚ users can ensure peak performance and extend the engine’s longevity. This manual remains an indispensable resource for anyone working with the Continental C90‚ fostering confidence in handling complex tasks effectively.

12.1 Summary of Key Points

The Continental C90 parts manual is a vital resource for maintaining and repairing the engine‚ offering detailed guidance on inspections‚ overhauls‚ and performance upgrades. It emphasizes safety‚ providing clear instructions for handling hazardous materials and ensuring compliance with aviation standards. Key sections cover engine assembly‚ troubleshooting‚ and tools required for efficient maintenance. By following the manual‚ users can extend the engine’s lifespan and optimize its performance. Its structured approach makes it an indispensable tool for both professionals and enthusiasts‚ fostering confidence in handling complex tasks effectively while ensuring operational safety and efficiency.

12.2 Final Thoughts on the Continental C90 Parts Manual

The Continental C90 parts manual is an indispensable guide for engine maintenance‚ offering comprehensive insights and practical solutions. It serves as a cornerstone for ensuring operational safety‚ performance‚ and longevity; By adhering to its guidelines‚ users can address common issues‚ implement upgrades‚ and maintain compliance with aviation standards. Its detailed structure and clear instructions make it a valuable tool for professionals and enthusiasts alike. Ultimately‚ the manual empowers users to maximize their engine’s potential while minimizing downtime and costs.

Leave a Reply